Industries

Heinrichs Messtechnik has been providing solutions for almost all applications in all areas of flow measurement technology for over a hundred years. High-precision and robust measurement technology for companies in all branches of industry are our speciality. We develop special solutions for every challenge, because we guarantee maximum flexibility and the highest development competence from a single source.

Our engineers are available for a free consultation.

Application

Chemical

Chemical industry

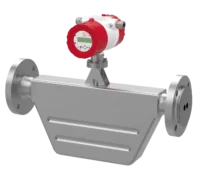

Heinrichs Messtechnik is one of the world’s most experienced suppliers of innovative products in process measurement technology. For more than 100 years, we have been developing extremely robust and reliable devices, especially for the field of flow measurement technology, which have set standards in terms of accuracy and reproducibility. With our extensive range, we are able to cover almost all flow applications in a modern chemical plant.

For processes with highly aggressive liquids, we manufacture flow meters from special materials such as high-purity tantalum, Hastelloy or PTFE.

Application

Petrochemical

Petrochemical industry

Petrochemical processes require particularly robust measurement technology. Flow meters in particular play a major role in the refinery process. Reliable measurement of all refined products with Coriolis flowmeters makes the production of many petrochemical end products effective in the first place. From DOWNSTREAM Refining and Chemicals to STORAGE and DISTRIBUTION, the highest demands are placed on the performance of the equipment. Accuracy and robustness are the most important features of Heinrichs measuring instruments. Highest durability of the products guarantees the stability of your process over decades. Some of our Coriolis mass meters have been in operation for more than 20 years and still provide stable measurements over this long period.

Application

Oil & Gas Industry

Oil & Gas Industry

When it comes to safe processes in the oil & gas industry, we are there. From the well to further processing in the refinery. You can expect the highest performance in measurement accuracy and robustness. From high-pressure injection systems for drill heads to fracking. Measure minute quantities under high pressure in all environmental conditions, such as those found on offshore platforms. In addition, precise measurements of these minute quantities can save considerable costs and protect the environment. At the same time, one achieves higher productivity and increases the yield. Unbeatable arguments. Flow measurements according to AGA/API standard, measurements according to MID/OIML standard.

For biogas plants, sewage treatment plants or for the use of hydrogen, we offer the oscillating flow meter DOG in all these areas of application gas volume measurements are carried out. Machine and plant manufacturers as well as customers from the process industry are highly satisfied with the reliable and durable devices from the well-known supplier KOBOLD Messring.

For years, KOBOLD Messring has had an oscillating flowmeter in its product range, which now convinces as the DOG-6 after an extensive revision with a clear division and new application possibilities.

DOG-4 and DOG-6 for a wide range of applications

The predecessor model, the oscillating flow meter DOG-4 is suitable for dry gases. As a special extension to this, the DOG-6 oscillating flowmeter has now been developed, which can measure both dry and moist gases.

Due to a separate unit design, it offers clear advantages over its predecessor model DOG-4, especially in applications with humid media, for example with natural condensate drainage. It is ideally suited for this thanks to its robust sensor. It is equipped with an optional shut-off valve, calibration software and a flow computer. Depending on the customer’s needs, the DOG-6, for which there is of course an individual calibration protocol for each unit, can be manufactured as an individual custom-made product. It can be used for a wide range of applications, as it is suitable for dry gases and mixed gases as well as for gas mixtures and humid gases.

Application

Power stations

Power stations

Our measurement technology is not only supplied to conventional power plants, but also to nuclear power plants, which is why we are very familiar with the requirements there. Processes in power plants must be continuously available; an interruption in the cooling circuit can lead to considerable problems. This is guaranteed with our magnetic inductive insertion sensor PIT – the sensor is optionally available with a removal device during operation for service purposes. Special is our normal.

Application

Ship building

Ship building

The marine industry has a wide range of requirements for measuring equipment. Measuring systems for this industry must be safe in the process, stable and insensitive to salty sea air, shocks, heat, cold and dust. The level of fuel and diesel tanks must be measured. In liquefied gas tankers, levels in the very low-density liquefied gas tank must be reliably and stably detected. Cooling and heating systems must be monitored. We measure bunker oil deliveries with high accuracy and ensure the highest accuracy in fuel refuelling with sophisticated software. Viscosity compensation and fraud-proof monitoring of the delivered bunker quantity save costs and time. In addition, we offer engine fuel control systems that provide a precise overview of the efficiency and use of ships with highly accurate consumption measurement of main and auxiliary engines, by satellite if desired. For ballast water systems we offer compact magnetic-inductive measuring devices that can also be used for large nominal diameters and can be installed anywhere in the ship.

Application

Laboratory equipment

Laboratory equipment

For more than 50 years, we have been manufacturing miniature measuring systems for the laboratory sector – where it all begins. For special requirements, also custom-made.

Application

Machinery & Plant Engineering

Machinery & Plant Engineering

Machines and plants are becoming increasingly complex and at the same time more powerful. However, higher performance also requires equally more powerful components in measurement operation. Heinrichs Messtechnik has been developing and manufacturing high-end sensor technology for industry for decades. From high pressure to high temperature – for high viscosity to high precision. We manufacture cost-efficient measuring devices for series systems that are not available off the shelf for the respective applications. We call this “Technology on Demand” – your requirements for performance and cost efficiency are our challenge.

Application

Water & waste water

water & waste water

Operators of water and wastewater networks increasingly have to monitor the efficiency of their processes and are therefore dependent on particularly reliable and easily deployable measurement technology. Precise measurements of water consumption in production processes are therefore a prerequisite for efficient water and wastewater management. Fresh or potable water networks often require an economical measuring solution where flow meters can be mounted and dismounted without interrupting the water supply. The proven magnetic inductive immersion probe PIT can be installed/removed during operation by means of an installation/removal device. Measurements in large pipe cross-sections are also cost-effective and do not require any modification of the pipe. Of course, we also offer solutions for smaller pipe cross-sections or use in-line flow meters.

Robert-Perthel-Straße 9, 50739 Köln

Robert-Perthel-Straße 9, 50739 Köln Tel.: +49 (221) 49708-0

Tel.: +49 (221) 49708-0

Fax: +49 (221) 49708-178

Fax: +49 (221) 49708-178